Search

Search

Enter part no, manufacturer part no, machine model or description

Browse by Application

Find parts to fit your specific Tractor Make/Model or Engine

Browse by Category

Select Engine Make

Select Vehicle Make

Essential Mechanics: Understanding Cylinder Head Gaskets in Tractor Engines

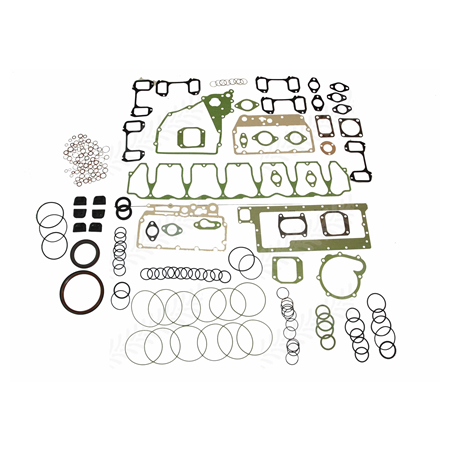

In the realm of agricultural machinery, the tractor stands out as a pivotal tool, crucial for a variety of farming tasks. At the heart of its robust performance lies the engine, a marvel of mechanical engineering. A key component often overlooked yet vital for engine efficiency and longevity is the cylinder head gasket. This indispensable part serves as the critical seal between the engine block and the cylinder head, ensuring optimal compression and preventing leakage of fluids and gases within the engine. Understanding the role, functionality, and importance of cylinder head gaskets in tractor engines not only enlightens one on the intricacies of tractor mechanics but also underscores the significance of regular maintenance and timely repairs for sustainable farming operations.

Detecting a problem with the cylinder head gasket in your tractor is crucial for maintaining its performance and preventing further damage. Here are some common signs that indicate a potential issue with the cylinder head gasket:

- Overheating Engine: One of the earliest signs of a failing cylinder head gasket is an overheating engine. The gasket plays a critical role in maintaining proper engine temperature. If it's damaged, it can lead to insufficient cooling, causing the engine to overheat.

- Spark Plug Issues: Damaged or fouled spark plugs can also be a sign. Coolant or oil leaking into the combustion chamber can leave deposits on the spark plugs.

- Loss of Power or Rough Operation: A damaged head gasket can cause a loss of engine compression, leading to a noticeable decrease in engine power, rough idling, or difficulty in starting the tractor.

- White Smoke from the Exhaust: White smoke emitting from the exhaust, especially if it's thick and continuous, can indicate coolant leaking into the combustion chamber. This is a classic symptom of a blown head gasket.

- Oil Contamination: If the head gasket is damaged, coolant can mix with the engine oil. This mixture often turns the oil into a milky white substance, visible on the oil cap or dipstick.

- External Leaks: A failing gasket may cause coolant or oil to leak externally from the space between the engine block and the cylinder head. You might notice this as a leak or wetness on the side of the engine.

- Bubbles in the Radiator or Coolant Reservoir: If combustion gases are leaking into the cooling system through a damaged head gasket, you may see bubbles forming in the radiator or coolant reservoir, often accompanied by the coolant overflow.

- Increased Coolant Consumption: A subtle but steady decrease in coolant levels, without any obvious leakage, can be a sign of a compromised head gasket, where coolant is being burned in the combustion chamber.

If you notice any of these symptoms, it's important to have your tractor inspected by a professional mechanic. Ignoring these signs can lead to more severe engine damage. Regular maintenance and timely repairs are essential to ensure the longevity and efficient performance of your tractor's engine.

The evolution of a tractor's cyclinder head gasket

The evolution of tractor cylinder head gaskets reflects advancements in materials, design, and engine technology. Here's a comparison between older and modern tractor cylinder head gaskets:

| Old Tractor Cylinder Head Gaskets | Modern Tractor Cylinder Head Gaskets |

|---|---|

|

|

Modern tractor cylinder head gaskets represent significant improvements over older ones in terms of materials, design, and performance. They are better equipped to handle the demands of contemporary engines, which are more powerful and operate under higher pressures and temperatures. This evolution mirrors the overall technological advancements in tractor and engine design.

Checking a cyclinder head gasket for damage

Visual Inspection

Surface Condition: Begin by examining the surface of the gasket for any signs of physical damage like cracks, breaks, or burns. These are often the most obvious indicators of a compromised gasket.

Gasket Compression: Check if the gasket appears compressed or thinner in certain areas, especially around the cylinders. Uneven compression can indicate a loss of sealing ability, leading to leaks.

Residue and Discoloration: Look for unusual residue or discoloration on the gasket surface. Oil or coolant stains can indicate leaks, while darkened or burnt areas may suggest overheating.

Bolt Torque and Alignment: Ensure that all bolts are torqued to the manufacturer's specifications. Misaligned or improperly torqued bolts can cause uneven pressure on the gasket, leading to damage.

Leak Detection

Coolant and Oil Leaks: Inspect the area around the cylinder head and engine block for any signs of external leaks. Coolant or oil seeping from the joint can be a clear indication of gasket failure.

Combustion Gases in the Cooling System: Use a coolant system pressure tester to check for the presence of combustion gases in the cooling system, which is a sign of a breached gasket.

Engine Performance Checks

Compression Test: Conduct a compression test on each cylinder. Variations in compression readings can suggest issues with the gasket, especially if adjacent cylinders have significantly lower compression.

Exhaust Analysis: Observe the exhaust while the engine is running. White smoke or the smell of coolant in the exhaust can indicate a breach in the gasket between the combustion chamber and the coolant passages.

Additional Considerations

Engine Overheating History: Inquire or check records for any history of engine overheating. Overheating can cause the gasket to fail and may not always leave an obvious trace on the gasket itself.

Recent Repairs or Overhaul: If the engine has recently been repaired or overhauled, ensure that the gasket and associated components were correctly installed and are compatible with the engine model.

Coolant and Oil Condition: Check the condition of the coolant and oil. Cross-contamination, such as oil in the coolant or coolant in the oil, is a strong indicator of gasket failure.

Inspecting a cylinder head gasket thoroughly involves a combination of visual checks, leak detection, performance testing, and considering the engine's history. It's essential to address any signs of damage immediately to prevent further engine complications. Regular maintenance and timely inspections are key to extending the life of a tractor's engine.

Why do modern gaskets fail?

Even though modern cylinder head gaskets are designed for durability and longevity, they can still fail due to various reasons. Understanding these causes can help in preventative maintenance and early detection of issues. Here are some common reasons for the failure of modern cylinder head gaskets:

- Overheating: This is one of the most common causes of gasket failure. If the engine overheats, it can cause the cylinder head to warp or even crack, leading to gasket failure. Overheating can be due to a variety of issues, such as a malfunctioning thermostat, clogged radiator, or a failure in the cooling system.

- Improper Installation: If the gasket is not installed correctly, it can fail prematurely. This includes incorrect torque on the head bolts, improper alignment, or contamination of the gasket surface during installation.

- Material Failure: Despite advances in materials, gaskets can still succumb to stress and environmental factors. Corrosion, extreme temperature changes, and material fatigue can all contribute to gasket failure.

- Engine Detonation or Pre-ignition: Abnormal combustion events like detonation or pre-ignition can cause excessive pressure and heat in the combustion chamber. This can damage the gasket, leading to its failure.

- Chemical Deterioration: Exposure to harsh chemicals, such as certain types of engine coolants or oil additives, can deteriorate the gasket material over time.

- Fluctuations in Engine Pressure: Regular fluctuations in engine pressure, especially in high-performance or heavily used engines, can strain the gasket.

- External Factors: Accidents or external damage to the engine can also impact the gasket, though such instances are rare.

- Wear and Tear: Even with robust construction, normal wear and tear over time can lead to the gradual degradation of the gasket.

- Poor Engine Maintenance: Lack of regular maintenance can lead to a variety of engine issues that indirectly cause gasket failure. For example, not changing the oil or coolant at recommended intervals can lead to the accumulation of contaminants that may harm the gasket.

- Design Flaws: In some cases, there may be design or manufacturing defects in the gasket or associated components, though this is less common with modern quality control standards.

While modern cylinder head gaskets are made to be more durable, they are not invulnerable. A combination of mechanical stresses, environmental factors, maintenance habits, and operational conditions can lead to their failure. Regular inspection and proper maintenance of the engine and its cooling system are key to extending the life of the gasket and ensuring the overall health of the engine.

In this post we covered several aspects related to tractor engine maintenance, focusing particularly on cylinder head gaskets. We began by discussing the role and importance of cylinder head gaskets in a tractor's engine, highlighting their function as a critical seal between the engine block and cylinder head.

We then moved on to the common signs indicating a potential issue with a tractor's cylinder head gasket. These signs included overheating, loss of power, white smoke from the exhaust, oil contamination, external leaks, bubbles in the radiator or coolant reservoir, increased coolant consumption, and spark plug issues. Next, we compared old and modern tractor cylinder head gaskets. This comparison included differences in materials, design, tolerance to irregularities, and how they handle heat and pressure. Modern gaskets, made from materials like multi-layer steel and advanced composites, were noted for their superior performance compared to their older counterparts.

Following this, we provided detailed information on what to look for when inspecting a cylinder head gasket for damage. This included visual inspection, leak detection, engine performance checks, and considering the engine's history. Lastly, we discussed why modern cylinder head gaskets, despite being built for durability, can still fail. The reasons included engine overheating, improper installation, material failure, engine detonation, chemical deterioration, fluctuations in engine pressure, wear and tear, poor maintenance, design flaws, and external factors. Overall, the article provided a comprehensive overview of the significance, inspection, and maintenance of cylinder head gaskets in tractor engines, as well as an understanding of their evolution and potential failure causes.

Disclaimer: MalpasDirect (Malpas Tractors Ltd, Curvica Ltd) does not provide any warranty or guarantee as to the accuracy of any information on this website and cannot accept liability for any errors or omissions. The information in this article are for general information purposes only. It does not constitute legal, technical and/or commercial advice and should not be relied upon as such. Specific advice should always be sought separately. Despite the our best efforts the information provided in this article may not be accurate, up to date or applicable to the circumstances of any particular case. MalpasDirect (Malpas Tractors Ltd, Curvica Ltd) also make no representations or warranties of any kind regarding the completeness or accuracy of the information contained herein and accepts no liability for loss or damage whatsoever and howsoever arising from reliance on it, regardless of whether such information originates from MalpasDirect (Malpas Tractors Ltd, Curvica Ltd). MalpasDirect (Malpas Tractors Ltd, Curvica Ltd) has no control over the content on any other website accessed through this website and accepts no liability for any loss or damage whatsoever and howsoever arising from reliance upon the content of such websites. MalpasDirect (Malpas Tractors Ltd, Curvica Ltd), regarding the content on the website cannot be liable to any person for any loss or damage which may arise from the use of the information contained in this article or on this website. These exclusions of liability will not apply to damages arising from death or personal injury caused by the negligence of MalpasDirect (Malpas Tractors Ltd, Curvica Ltd) or any of its employees or agents or of a reviewer or contributor of content.