Search

Search

Enter part no, manufacturer part no, machine model or description

Browse by Application

Find parts to fit your specific Tractor Make/Model or Engine

Browse by Category

Select Engine Make

Select Vehicle Make

The Heart of the Farm: Why Proper Tractor Engine Maintenance is Vital for Farmers

For farmers, the tractor is often the backbone of their operations, enabling them to efficiently cultivate fields, transport goods, and perform a multitude of essential tasks. At the core of this agricultural workhorse lies its engine, the beating heart of the farm. Just as a healthy heart is crucial for a person's well-being, a well-maintained tractor engine is paramount to a farmer's success. In this article, we will explore the reasons why looking after tractor engine parts is of utmost importance to farmers and how proper maintenance can ensure the longevity and productivity of this indispensable piece of machinery by using quality replacement .

What are the most common issues with tractor engines?

Tractor engines, like any mechanical system, can encounter a range of common issues over time. Farmers and tractor owners should be aware of these issues to address them promptly and maintain the reliability of their equipment. Here are some common problems with tractor engines:

- Fuel System Problems: Tractors often suffer from fuel-related issues, such as clogged fuel filters, contaminated fuel, or fuel injector problems. These issues can lead to poor engine performance, reduced power, and increased fuel consumption.

- Overheating: Overheating can occur due to coolant leaks, malfunctioning thermostats, or clogged radiators. It's crucial to monitor engine temperatures and address overheating promptly to prevent engine damage.

- Oil Leaks: Oil leaks from the engine or its components can result in reduced lubrication, which can lead to engine wear and even catastrophic failure if not addressed.

- Exhaust System Issues: Problems in the exhaust system, including exhaust leaks, damaged mufflers, or clogged catalytic converters, can affect engine efficiency and emissions.

- Air Intake Issues: Clogged or dirty air filters can restrict the flow of air into the engine, reducing combustion efficiency and power output.

- Electrical System Failures: Electrical problems, such as a weak battery, faulty alternator, or malfunctioning ignition system, can lead to starting issues and poor engine performance.

- Compression Problems: Low compression in the engine cylinders can result from worn piston rings or damaged valves, causing reduced power and increased fuel consumption.

- Cooling System Failures: A malfunctioning water pump, radiator, or cooling fan can cause the engine to overheat, leading to potential damage.

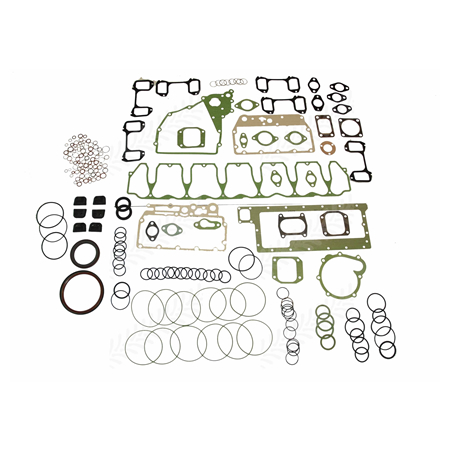

- Gasket and Seal Failures: Leaking gaskets and seals can lead to oil or coolant leaks, which can be costly to repair and harm engine performance.

- Carbon Deposits: Over time, carbon deposits can accumulate in the combustion chamber, valves, and pistons, reducing engine efficiency and power.

- Lack of Regular Maintenance: Neglecting routine maintenance tasks like oil changes, filter replacements, and scheduled inspections can lead to various engine issues over time.

- Excessive Wear and Tear: Continuous use without proper maintenance can result in general wear and tear of engine components, affecting overall performance and longevity.

To mitigate these common issues and ensure the longevity and reliability of tractor engines, farmers should adhere to a regular maintenance schedule, promptly address any warning signs or unusual sounds, and consult with experienced technicians for repairs and servicing when needed. Regular maintenance not only saves time and money but also helps ensure that the tractor remains a dependable workhorse on the farm so ensure that you use quality replacement tractor engine parts.

Interpreting Engine Smoke: What Different Colours Mean

A smoking engine can be an indicator of various underlying problems, and the colour of the smoke can provide valuable clues about the nature of the issue. Different coloured smoke can signify different problems with the engine. Here's what each colour of smoke typically indicates:

Blue Smoke:

Blue smoke is often a sign of burning oil. It indicates that engine oil is making its way into the combustion chambers and getting burned along with the fuel. This can be caused by worn piston rings, damaged valve seals, or a malfunctioning PCV (Positive Crankcase Ventilation) system. Burning oil can lead to reduced engine performance, increased emissions, and potential damage to the catalytic converter (when fitted).

White or Gray Smoke:

White or gray smoke usually suggests that coolant or water is entering the combustion chambers and getting vaporized. This can be caused by a blown head gasket, a cracked cylinder head, or a damaged cylinder wall. It's a serious issue as it can lead to engine overheating and significant damage if not addressed promptly.

Black Smoke:

Black smoke is a sign of an overly rich fuel-air mixture, meaning there's too much fuel in relation to the amount of air in the combustion process. Common causes include a clogged air filter, a malfunctioning fuel injector, a faulty oxygen sensor, or incorrect timing. Black smoke can reduce fuel efficiency, increase emissions, and lead to carbon buildup in the engine.

Excessive White Smoke at Startup:

If you notice white smoke primarily during startup and it disappears once the engine warms up, it may not necessarily indicate a problem. This can be normal condensation in the exhaust system evaporating as the engine heats up. However, if the white smoke persists, it could still indicate coolant entering the combustion chamber.

Excessive Black Smoke during Acceleration:

A sudden burst of black smoke during heavy acceleration can be normal for some turbocharged diesel engines. However, if this occurs continuously or under light load conditions, it may indicate an issue with the fuel system or turbocharger.

It's essential to address any abnormal smoke from your engine promptly. Ignoring these signs can lead to more severe engine damage and increased repair costs. If you observe unusual smoke from your engine, it's advisable to consult a qualified mechanic or technician who can diagnose the problem accurately and perform necessary repairs to keep your engine running smoothly.

Compression testing?

Compression testing is a diagnostic procedure used to assess the health and performance of an internal combustion engine, such as those found in cars, trucks, motorcycles, and other machinery. It measures the compression pressure within the engine's cylinders, which is a crucial indicator of engine condition. Compression testing is commonly used in engine diagnostics to identify issues like worn piston rings, damaged valves, or head gasket problems.

- Compression Tester:

- The primary tool used in compression testing is a compression tester or compression gauge. This device consists of a pressure gauge with a hose and a threaded adapter that screws into the spark plug hole of the cylinder being tested.

- Spark Plug Socket or Adapter:

- To access the cylinder, you'll need to remove the spark plug. A spark plug socket or adapter is used for this purpose.

-

- Battery or External Power Source:

- In some cases, you may need a stable power source to crank the engine during the compression test. This is typically necessary for testing multiple cylinders, as it requires the starter motor to turn the engine.

- Safety Gear:

- Safety glasses and gloves are essential when performing a compression test to protect against any potential fuel or oil spray.

The basic compression testing procedure typically includes some of the following steps:

- Prepare the Engine:

- Ensure the engine is off and at room temperature. Remove the spark plug from the cylinder you want to test.

- Install the Compression Tester:

- Screw the compression tester into the spark plug hole of the chosen cylinder. Ensure it's securely attached.

- Disable the Ignition System:

- To prevent the engine from starting while you perform the test, disable the ignition system, either by disconnecting the ignition coil or the fuel injection system.

- Crank the Engine:

- With the compression tester attached, crank the engine using the starter motor or an external power source (if necessary) for a few seconds. This allows the gauge to register the maximum compression pressure achieved during a full rotation of the engine.

- Read the Pressure:

- Observe the pressure reading on the compression tester gauge. Record the result for future reference.

- Repeat for Other Cylinders:

- If you're testing multiple cylinders, repeat the process for each one.

- Interpret the Results:

- Compare the compression readings between cylinders. A significant variation in compression pressure between cylinders may indicate an issue with the engine, such as worn rings, damaged valves, or a head gasket problem.

Compression test or leakdown test?

Both a compression test and a leakdown test are valuable diagnostic procedures for assessing the condition of a tractor engine or any internal combustion engine. They provide different types of information, and the choice between them depends on the specific diagnostic goals and the level of detail required. Let's briefly compare these two tests:

| Compression Test: | Leakdown Test: |

|---|---|

|

|

If you suspect general issues with engine compression or want a quick assessment, a compression test is a suitable choice. However, if you require more detailed information about the condition of individual cylinders or need to pinpoint specific problems, a leakdown test is the preferred option. Many professional mechanics use both tests in conjunction to get a comprehensive picture of an engine's health, especially when dealing with complex or stubborn performance issues.

In this topic, we discussed the importance of tractor engine maintenance, common issues that can arise with tractor engines, and how to interpret different colors of smoke emitted from an engine. We also explained what compression testing is, its associated equipment, and compared it to a leakdown test for tractor engine diagnostics. In summary, proper maintenance is crucial for the longevity of tractor engines, and addressing common issues promptly is essential. Different colors of smoke can indicate various engine problems. Compression testing and leakdown testing are both valuable tools for diagnosing engine issues, with compression testing providing a general assessment and leakdown testing offering more detailed insights into cylinder health. Choosing between the two tests depends on the specific diagnostic needs and goals.

Disclaimer: MalpasDirect (Malpas Tractors Ltd, Curvica Ltd) does not provide any warranty or guarantee as to the accuracy of any information on this website and cannot accept liability for any errors or omissions. The information in this article are for general information purposes only. It does not constitute legal, technical and/or commercial advice and should not be relied upon as such. Specific advice should always be sought separately. Despite the our best efforts the information provided in this article may not be accurate, up to date or applicable to the circumstances of any particular case. MalpasDirect (Malpas Tractors Ltd, Curvica Ltd) also make no representations or warranties of any kind regarding the completeness or accuracy of the information contained herein and accepts no liability for loss or damage whatsoever and howsoever arising from reliance on it, regardless of whether such information originates from MalpasDirect (Malpas Tractors Ltd, Curvica Ltd). MalpasDirect (Malpas Tractors Ltd, Curvica Ltd) has no control over the content on any other website accessed through this website and accepts no liability for any loss or damage whatsoever and howsoever arising from reliance upon the content of such websites. MalpasDirect (Malpas Tractors Ltd, Curvica Ltd), regarding the content on the website cannot be liable to any person for any loss or damage which may arise from the use of the information contained in this article or on this website. These exclusions of liability will not apply to damages arising from death or personal injury caused by the negligence of MalpasDirect (Malpas Tractors Ltd, Curvica Ltd) or any of its employees or agents or of a reviewer or contributor of content.