Search

Search

Enter part no, manufacturer part no, machine model or description

Browse by Application

Find parts to fit your specific Tractor Make/Model or Engine

Browse by Category

Select Engine Make

Select Vehicle Make

Walterscheid PTO

MalpasDirect is pleased to offer you this extensive range of Walterscheid PTO shafts and spare parts to compliment or replace your existing PTO selection. Walterscheid is part of the GKN Group, a global engineering business designing, manufacturing and servicing systems and components for most of the world’s leading machinery manufacturers. GKN is a global tier one supplier of power management products, systems and service solutions to the leading agricultural machinery manufacturers and specialises in the supply of PTO shafts, gears and spare parts.

Product Range

You can view our full range of PTO parts or filter your search by selecting from our most popular categories below:

PTO Drive Shafts

Since the early days farmers have always sort ways to increase productivity and efficiency around the farm, one of the key areas to assist the farmer is incorporating machines into the daily life. The first machines relied on belt driven systems powered by steam engines but these did have their draw backs, the main one being that the machinery had to be stationary. However, over time the system was improved which allowed for traction engines to pull the implement and power it using the rotation of the engines wheels to power the implement, which was fine until the traction engine stopped moving. This called for a new system to use the tractors engine to power the implement without any limitations. The first marketable PTO system was introduced by International Harvester around the late 1910's which was closely followed by other leading manufacturers of the time.

Today, the drive shaft made by Walterscheid is composed of components with the highest quality which can be configured in such a way that they will meet all necessary requirements perfectly. Their products are suitable for applications ranging from small, economical solutions utilised in standard applications to high-performance combinations intended for continuous use and needed to deliver the highest possible drive power. They offer different series that are suitable for different application profiles.

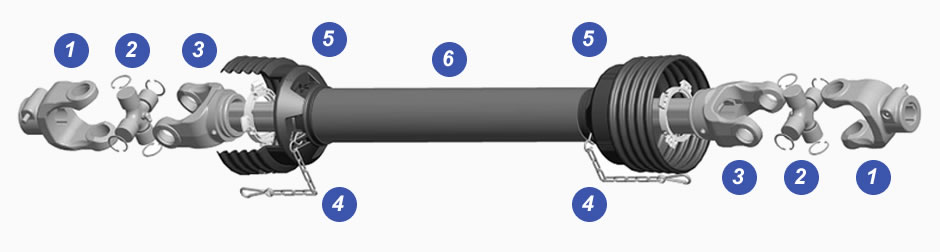

PTO Shaft Components

| 1. Outer Yoke 2. Universal Joint |

3. Inner Yoke 4. Chain |

5. PTO Guard 6. PTO Tube |

FAQ

What precations should I take when working with a PTO shaft?

Caution - only work with a completely guarded drive.

- It is forbidden to use the PTO drive shaft without a guard, with a damaged guard, or without correctly using the safety chain (if necessary).

- Before each use, check whether all PTO drive shaft safety devices are fitted and fully functional.

- Always use original Walterscheid parts when replacing or retrofitting damaged or missing parts, observing the applicable instructions.

- Structural modifications other than those described in these Service Instructions are not permissible.

- DO NOT TOUCH! - PTO drive shaft components (especially clutches) can reach high temperatures.

- Keep out of the danger area of rotating parts. Wear appropriate, tight-fitting clothing for safety.

- Only transport the PTO drive shaft in horizontal position. (Risk of accident due to the shaft falling apart.)

- Do not use the PTO drive shaft as a step or support.

- Prior to maintenance and repair work, switch off the engine, remove the ignition key and wait until all moving parts of the machine have come to a complete halt.

- Operate stationary machines (pumps, generators, blowers, etc.) only with a correctly coupled tractor or with a special mechanical connection and sufficient overlap of the profile tubes.

- The use of profile extensions / adapters on the PTO drive shaft is not permissible.

What to look for when choosing a PTO shaft

Unfortunately all vehicle/implement PTO connection dimensions are not all the same, otherwise it would be quite easy to select a common sized power take off shaft for any mechanical combinations. So what information do you need to have to ensure that your PTO connects correctly to your tractor and implement? This may seem a bit daunting but it can be simplified in 3 easy steps;

- Step 1 (PTO Shaft Type) - The first step in identifying a suitable replacement PTO assembly or component parts is to determine the "Series" (and "Type" where applicable) of the PTO shaft. The most common styles of PTO shafts are often referred to as "German" or "Italian" style. You can identify the series/type of a PTO shaft by looking at the Shaft Profile of the inner and outer tubes and cross reference that with the dimensions of the universal joint (measurements AØ and A) used. We will select the required length of the shaft in a later step.

- Step 2 (Tractor connection) - What type of connection is used for the tractor end? These connections can vary and may have a Quick Release mechanics', or be Wide Angle or have an Overrun Clutch.

- Step 3 (Implement Connection) - What type of equipment will be attached at the over end will depend on the connection required, if you're unsure then check your documentation or contact us with your enquiry.

A brief history of Walterscheid

For over 100 years Walterscheid have being manufacturing goods for a wide variety of applications. Their first products were manufacturing sprockets for bicycles in 1919 in Siegburg. By 1934 the company has grown quickly and now forges axles and axle shafts for vehicles, which become the foundation of the company’s future success. In 1952 the team opens up a new business area, the agricultural sector, by making drive shafts with an innovative guard. By 1978 the company continued its growth with expansion witihin Europe and then quickly further afield branching out to worldwide operations.