Search

Search

Enter part no, manufacturer part no, machine model or description

Browse by Application

Find parts to fit your specific Tractor Make/Model or Engine

Browse by Category

Select Engine Make

Select Vehicle Make

Looking After Your Tractor Engine

The engine is considered the heart of a tractor and other powered agricultural machinery. Without a properly functioning engine, the tractor cannot perform its intended functions, and productivity can be severely impacted. Regular maintenance and upkeep of the engine are essential to keep it in optimal condition. This includes oil changes, air filter replacements, and checking and maintaining proper fluid levels. It is also important to follow the manufacturer's recommended maintenance schedule and to address any issues promptly to prevent further damage. Properly maintaining the engine not only improves performance but also extends the life of the machinery, reduces the risk of breakdowns and costly repairs, and can even improve fuel efficiency. Therefore, it is crucial to prioritize engine maintenance as a crucial aspect of agricultural machinery upkeep.

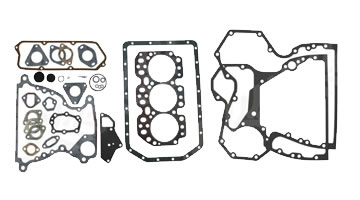

Engine parts are subject to wear and tear due to various factors such as friction, heat, and stress. Proper maintenance can help prolong the life of these parts, but eventually, they will wear out and need to be replaced. Some common engine parts that may need to be replaced include spark plugs, air filters, oil filters, timing belts, water pumps, and various gaskets and seals. These components play a vital role in the proper functioning of the engine, and if they become worn or damaged, they can cause performance issues, decreased fuel efficiency, and even engine failure. Regular maintenance and inspections can help identify parts that need to be replaced before they cause significant damage or failure. It's essential to follow the manufacturer's recommended maintenance schedule and replace parts with high-quality components that meet the manufacturer's specifications. In summary, while proper maintenance can help prolong the life of engine parts, replacement is inevitable. Identifying and replacing worn or damaged components can prevent more significant issues and ensure the engine operates at its best performance.

Shop for engine parts by category

Engine parts that make a difference for modern tractors

Modern tractors have advanced significantly in terms of performance, efficiency, and reliability, and this is largely due to the evolution of engine technology. Here are some engine parts that make a difference for modern tractors:

- Electronic Control Module (ECM): The ECM is a computerized system that controls various engine functions, including fuel injection, ignition timing, and emissions. It can adjust engine performance based on various factors, such as load and operating conditions, to optimize fuel efficiency and reduce emissions.

- Turbocharger: A turbocharger increases engine performance by forcing more air into the combustion chamber, which results in more power and improved fuel efficiency. It is especially useful in tractors that need to perform heavy-duty tasks such as plowing, tilling, or hauling heavy loads.

- Common Rail Fuel Injection: Common rail fuel injection is a system that uses high-pressure fuel to inject precise amounts of fuel directly into the combustion chamber. This system results in better fuel efficiency, lower emissions, and improved engine performance.

- Exhaust Gas Recirculation (EGR): EGR is a system that recirculates a portion of the exhaust gases back into the engine. This reduces the amount of oxygen in the combustion chamber, which lowers the combustion temperature and reduces NOx emissions.

- Diesel Particulate Filter (DPF): A DPF is a device that traps and removes particulate matter from the exhaust stream. It is effective in reducing emissions of particulate matter, which can be harmful to human health and the environment.

These engine parts, along with other advances in engine technology, have made modern tractors more efficient, reliable, and environmentally friendly.

Common Issues and Solutions For Tractor Modern Engines

Problem: Overheating

Solution: Make sure the radiator is clean and free of debris. Check coolant levels regularly and ensure that the coolant is the correct type and mixture for your tractor. If your tractor is still overheating, consider installing a larger radiator or adding an auxiliary cooling fan.

Problem: Starting difficulties

Solution: Check the battery and charging system. Clean and tighten all connections, replace any damaged or corroded cables, and ensure that the battery is fully charged. If the starter motor is still struggling to turn the engine, consider replacing it.

Problem: Oil leaks

Solution: Check all gaskets and seals, and replace any that are worn or damaged. Tighten all bolts and connections, and make sure that the oil level is always within the recommended range.

Problem: Dirty or clogged air filter

Solution: Replace the air filter regularly, according to the manufacturer's recommendations. A dirty or clogged air filter can reduce engine performance and fuel efficiency.

Problem: Fuel system issues

Solution: Check the fuel lines, filters, and injectors regularly. Replace any damaged or clogged parts, and make sure that the fuel is clean and free of water or other contaminants. Consider adding a fuel stabilizer to protect against corrosion and extend the life of the fuel.

Problem: Lack of power

Solution: Check the air filter, fuel system, and exhaust system for any issues. Make sure that the engine is properly tuned, and consider upgrading to a higher performance air filter or exhaust system if necessary.

Remember, regular maintenance and proper care are the keys to keeping your tractor engine running smoothly and reliably. Don't hesitate to consult your owner's manual or a qualified mechanic if you have any questions or concerns about your engine's health.

Adblue - a problem for a modern day solution - preventing crystallisation

AdBlue is a fluid that is used in vehicles with Selective Catalytic Reduction (SCR) technology to reduce emissions of nitrogen oxides (NOx). AdBlue contains urea, which can crystallize under certain conditions, such as exposure to high temperatures or air. Crystallization can cause blockages in the AdBlue system and affect the performance of the SCR system.

To prevent crystallization when using AdBlue, here are some tips:

- Store AdBlue in a cool, dry place: AdBlue should be stored in a cool, dry place away from direct sunlight and heat sources. Ideally, the temperature should be between 12 and 25 degrees Celsius. AdBlue should be used within 6 to 12 months of the date of manufacture to ensure maximum quality.

- Use only high-quality AdBlue: AdBlue should meet the ISO 22241 standard and be certified by the German Association of the Automotive Industry (VDA). Using low-quality or contaminated AdBlue can cause damage to the SCR system and increase emissions.

- Keep the AdBlue tank clean: The AdBlue tank should be kept clean and free of debris to prevent contamination. If the tank becomes contaminated, it should be drained and cleaned before adding new AdBlue.

- Do not mix AdBlue with other fluids: AdBlue should not be mixed with other fluids, such as diesel or water, as this can cause damage to the SCR system and increase emissions.

- Follow manufacturer's recommendations: Always follow the manufacturer's recommendations for the use and storage of AdBlue. This includes the recommended intervals for topping up the AdBlue tank and any other maintenance requirements for the SCR system.

By following these tips, you can help prevent crystallization and ensure that your AdBlue system operates efficiently and effectively.

Maintaining a healthy radiator in a tractor

Maintaining a healthy radiator is crucial to keeping your tractor engine cool and operating at optimal performance. Here are some tips to help you maintain a healthy radiator in your tractor:

- Check the coolant level: The coolant level in the radiator should be checked regularly, especially before starting the tractor. Low coolant levels can cause the engine to overheat, which can result in costly damage. Make sure the coolant level is within the recommended range and add more if necessary.

- Use the correct coolant: Make sure that the coolant you use is the correct type and mixture recommended by the manufacturer. Using the wrong coolant can cause corrosion or other damage to the radiator and cooling system.

- Keep the radiator clean: Dirt and debris can clog the fins of the radiator and reduce its effectiveness. Clean the radiator periodically with a soft brush or compressed air to remove any debris or dirt buildup.

- Check for leaks: Look for any visible signs of coolant leaks, such as wet spots or stains around the radiator or hoses. A leak can cause the engine to overheat and damage the radiator and other components.

- Replace the radiator cap: The radiator cap is a critical component of the cooling system that maintains the proper pressure inside the radiator. If the cap is worn or damaged, it can cause coolant loss or overheating. Replace the radiator cap periodically, according to the manufacturer's recommendations.

- Service the cooling system: The cooling system should be serviced periodically, according to the manufacturer's recommendations. This includes draining and flushing the system and replacing the coolant and any worn or damaged components, such as hoses or the thermostat.

By following these tips, you can help maintain a healthy radiator and ensure that your tractor engine stays cool and operates at optimal performance. It's also important to refer to your tractor owner's manual for specific maintenance requirements.